In modern automotive assembly lines, precision and real-time decision-making are essential to maintain production speed without compromising quality. Mistakes like misalignment or suspension failure can delay production, increase costs, or cause safety and compliance issues.

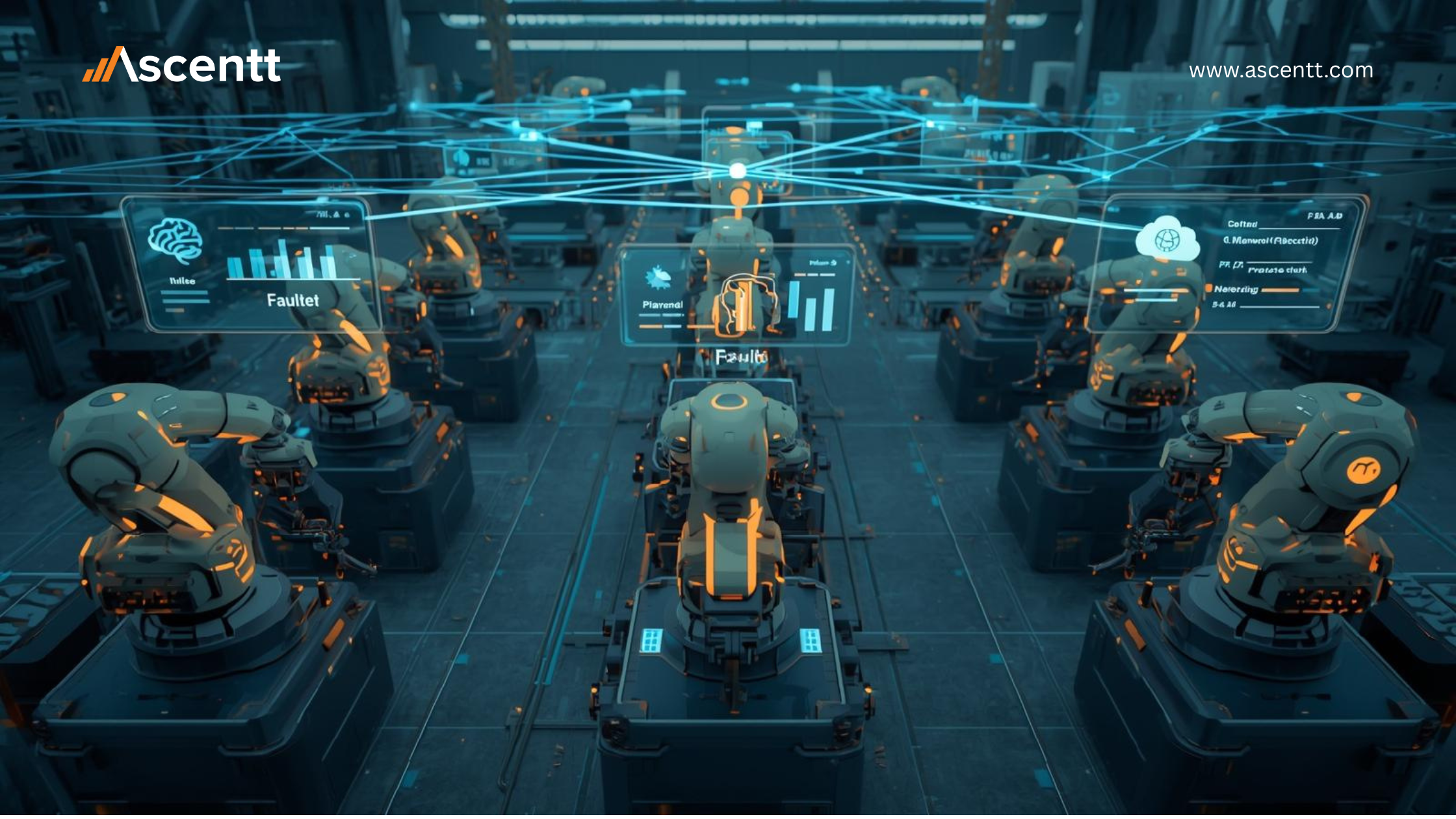

Vision AI is quickly becoming indispensable in overcoming such issues. A form of artificial intelligence, Vision AI systems can monitor activities in real-time using cameras and make decisions based on what they observe. Unlike traditional automation that follows rigid rules, Vision AI learns to recognize patterns, just like a human inspector would, only faster and more consistently. It enables instant, consistent inspections that align with broader QC and automation goals, reducing errors and streamlining operations.

A major car manufacturer sought a better and smarter way to identify correct wire colors for safety and efficiency. Here’s the story of how this problem was tackled using Vision AI and what it says about the future of manufacturing.

The Problem: Manually Inspecting Wire Colors

In producing one mid-size SUV, technicians of a major car manufacturer had to verify wires controlling lighting, sensors, entertainment systems, and more. However, manual verification of colors, especially under artificial lighting, was becoming increasingly complex.

Human inspectors had to look at dozens of wires in a small space, compare them to reference charts, and catch mistakes in real time. This process was slow and error-prone. Technicians got tired quickly, especially when lighting conditions varied. Subtle errors went unnoticed, often until after the car was fully built.

The consequences were costly:

- Rework added time and labor

- Faulty wiring led to inspection failures

- Skilled technicians were stuck doing repetitive tasks

The Solution: Using Vision AI for Wire Color Detection

The manufacturing company partnered with Ascentt to implement a Vision AI solution that could visually check wires quickly, accurately, and consistently. The quality control solution was built to work in real time, without delay or pause, and conduct continuous, silent verification in the background.

- Image Capture: Thousands of images from real assembly lines were captured. These showed the wire harnesses in different lighting, angles, and arrangements.

- Model Training: Each image was labeled by hand to train the AI model. The model was taught to recognize subtle differences in wire colors, even under varying lighting conditions.

- Assembly Line Integration: The Vision AI solution was integrated into the assembly line camera system for real-time image recognition, error flagging, and reporting.

- Alerts and Notifications: As each vehicle passed, the Vision AI system instantly scanned the wires, identified their colors, and checked them against the correct configuration. If a color mismatch or missing wire was detected, the system flagged it and alerted the team.

Results and Business Impact

After deploying the Vision AI solution, the automotive manufacturer saw significant improvements almost immediately:

- Inspection time dropped by nearly a third. The system could verify wires in seconds, consistently and without second-guessing.

- Mistakes were caught early in the manufacturing lifecycle. Instead of finding issues at the end of the line, problems were spotted when they happened, reducing costly rework.

- First-time-right scores improved. There were fewer missed errors, and more vehicles passed QC on the first try.

- Worker productivity increased. Skilled technicians could now focus on tasks that truly needed human attention, instead of repetitive visual QC checks.

- Scalability became easier. The team realized that if Vision AI could master wire colors, it could also be trained to handle other visual inspections.

The Bigger Picture: Vision AI’s Growing Role in Quality Control

Vision AI is quickly becoming a cornerstone of smart manufacturing, far beyond wire color detection. Its ability to learn from real-world visual data makes it highly adaptable for various quality control tasks, such as surface defect detection, label verification, and parts presence checks.

Platforms like Ascentt’s demonstrate how AI agents can be embedded into enterprise workflows, trained for specific, high-precision roles once dependent solely on human expertise. This shift improves consistency and speed and lays the groundwork for a more intelligent, responsive factory floor. Vision AI can be trained to handle many kinds of visual tasks on the production floor:

- Spotting surface scratches or dents

- Verifying the presence of parts or screws

- Reading and checking labels

- Making sure seals or gaskets are in place

And because it’s flexible, the same system can evolve as the product changes. There’s no need to reprogram every time a new model rolls out. This opens a new way of thinking for manufacturing leaders: instead of building new models from scratch, they can now train and retain existing systems to fit the use case at hand.

From Proof-of-Concept to Scalable Manufacturing AI: The Road Ahead

Vision AI has broad applicability across automotive manufacturing, offering an innovative, flexible way to automate visual inspection and quality control tasks that were once manual and error-prone.

At Ascentt, we empower manufacturers to standardize quality checks, reduce human error, and scale automation across lines and plants. Our Vision AI solution helps establish a more efficient, accurate, and intelligent production environment.

Ready to identify the proper use cases and get started? Check out our Asc AI solution today!

FAQs

What are the main benefits of implementing Vision AI in automotive manufacturing?

Key benefits of vision AI in automotive manufacturing include:

· Reduced inspection time

· Early error detection

· Minimized rework

· Faster time-to-market

· Better worker productivity

Can a Vision AI system be adapted for other quality control tasks beyond wire color detection?

Vision AI systems are flexible and can be trained for other use cases such as detecting surface defects, verifying parts presence, reading labels, and checking seals.