The idea that we should only fix things that are broken seems outdated for modern, hyperconnected, just-in-time production environments. When equipment is left to break before it is fixed, the results are expensive, unexpected downtime that impacts worldwide supply chains and flow-on effects across whole industries.

Particularly common in the automotive industry, 25% of manufacturers estimate the yearly cost of an idle production line at a major plant to be as much as a sizable $695 million – 1.5X itself over five years. Downtime in heavy industry cost around $59 million in 2020, which is 1.6X more than in 2019. Unplanned downtime now accounts for 11% of income among the 500 biggest firms worldwide, and these losses reach $1.4 trillion – almost equivalent to Spain’s GDP for a year! (Source: Siemens)

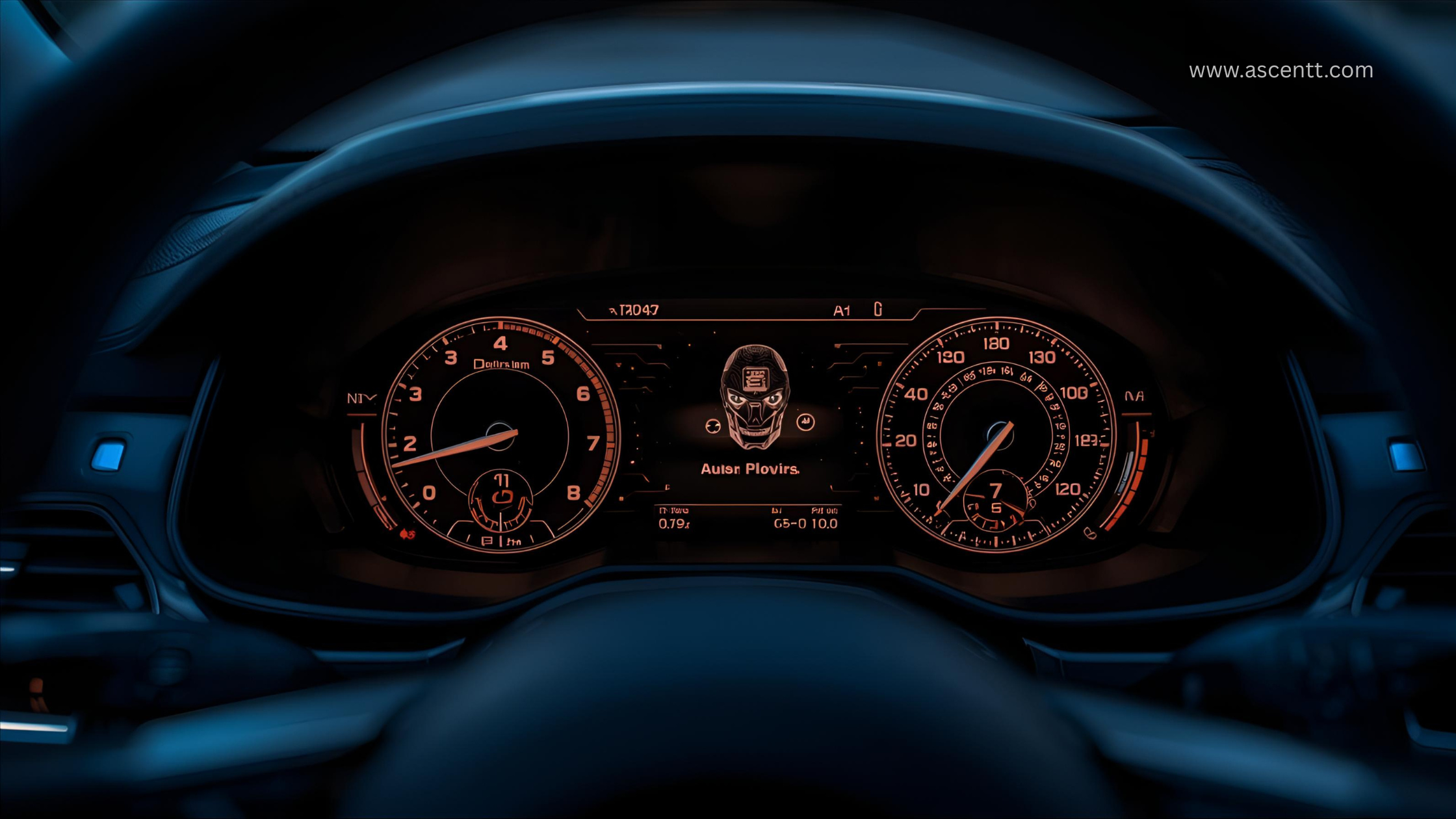

These statistics highlight the importance of adopting AI-based predictive maintenance for car manufacturers and industrial producers, enabling prediction of failures before they occur. This removes surprises and allows for smarter and more proactive decisions throughout the organization.

What Makes AI‑Driven Predictive Maintenance Truly Enterprise‑Grade?

The fact is that AI-powered predictive maintenance goes beyond just forecasting which component will fail. In order for it to work enterprise-wide, it must unite different levels of data intelligence, integration, and actionability.

Core Enablers of Enterprise-Grade Predictive Maintenance:

- Condition Monitoring: Continuous monitoring of equipment performance, utilizing real-time data sourced from temperature, vibration, and pressure sensors.

- Telematics: Connected vehicles are fed with telematics data – from location to usage patterns – speed, braking behavior, and so on into the predictive models to forewarn increasingly evident issues.

- Sensor-Generated Analytics: Pattern identification for impending breakdowns will be carried out on aggregated data from thousands of data points generated through IoT components.

- Predictive Failure Models: High-end ML models are trained on the basis of historical maintenance records, environmental data, and real-time inputs, to catch early failure signs.

Integrated Systems Approach:

Predictive maintenance is only as useful as its ability to trigger action within enterprise workflows. Integration with:

- ERP (Enterprise Resource Planning) systems ensures that replacement parts are automatically ordered in advance.

- CMMS (Computerized Maintenance Management Systems) allows automatic scheduling of field technicians and preventive actions.

This end-to-end integration turns predictions into timely interventions, drastically reducing mean time to repair (MTTR) and maximizing uptime.

Digital Twins & Telematics – Building a Live Virtual Sensor Network

A key innovation enabling smarter predictive maintenance is the digital twin – a virtual replica of a physical asset that continuously mirrors real-world conditions.

In automotive manufacturing, digital twins powered by telematics and sensor data allow automakers to simulate, monitor, and optimize the entire lifecycle of a vehicle component in real time.

Why It Matters:

- Live visibility into component health without physical inspection.

- Simulation of different operational scenarios for stress testing.

- Real-time adjustments to maintenance schedules based on actual wear-and-tear.

These “virtual models“ are dynamically evolving. They continue to learn from inputs from vehicle telematics systems so that a centralized platform can track and anticipate the conduct of thousands (or millions) of vehicles and parts around the world.

Optimizing Model Scheduling – When to Run AI vs Just‑in‑Time Maintenance

Running AI models for maintenance predictions is not a “one-size-fits-all“ affair but rather a fine-tuning between batch inference (periodic, large-scale analysis) and real-time inference (on-the-fly predictions).

Batch vs Real-Time Inference:

- Batch Processing is ideal for historical trend analysis, component lifecycle predictions, and fleet-level optimizations. It’s efficient but may miss real-time anomalies.

- Real-Time Inference ensures immediate alerts for critical failures (e.g., engine overheating), ideal for mission-critical systems.

Maintenance Scheduling Trade-offs:

- Running too many models in real time can strain resources.

- Relying only on batch may lead to missed incidents.

- The optimal strategy combines both: long-term planning with short-term agility.

This hybrid approach ensures maintenance is neither too early (increasing costs) nor too late (increasing downtime), but “just in time“, driven by intelligent AI-triggered decisions.

Success at Scale – Ascentt's Vertical AI in Action

Ascentt, with over 18 years of engineering real-world impact, delivers Vertical AI solutions – tailored for specific industries like automotive and heavy machinery.

What is Vertical AI?

Unlike general-purpose platforms like ChatGPT or Bard, Vertical AI applies an ML and deep industry knowledge combination to provide contextual insights, hence predicting faster ROI in a complex enterprise scenario.

Here, in fact, the Vertical AI market is projected to increase from $12.9 billion in 2024 to $115.4 billion by 2034. (Source: Market.US)

Why Industry-Specific AI Matters: Main Advantages

- Built-in domain intelligence → AI understands industry-specific terminology, workflows, and anomalies

- Smart, streamlined data flows → Integrated with enterprise systems like CMMS, ERP, and telematics

Automotive-Specific Challenges:

- High-frequency, high-volume connected vehicle (CV) data

- Complex lifecycle management of vehicle components

- Shifting user behavior driven by EVs and autonomous technologies.

Ascentt’s AI-Powered Automotive Use Cases

- Connected Vehicle Data Optimization Agent

- Processes large-scale CV data using spark-based algorithms

- Connects vehicle data to enterprise systems to improve product quality and customer experience

- Delivered 4X faster insights and reduced operational costs by 40X

- Vehicle Health Diagnostics Agent

- Merges vehicle diagnostic trouble codes (DTCs) with behavioral and sensor data

- Scores trips for vehicle stress and wear patterns

- Forecasts upcoming maintenance needs

- Result: $28M savings via proactive maintenance and improved vehicle reliability

- PII Obfuscation AI Agent for Vehicle Data

- Uses AI to anonymize sensitive information like faces and license plates in telematics video feeds

- Ensures privacy compliance across geographies

- Enables secure, global-scale data usage without breaching privacy laws

These are not generic solutions. Each model is fine-tuned for the automotive domain, developed through years of hands-on experience, and deployed within real-world environments – not lab settings.

Conclusion

For automakers and industrial manufacturers, predictive maintenance is no longer optional—it’s a strategic imperative. The cost of waiting till something breaks is far too high. The way forward is AI that knows something is wrong before you do: models built on your enterprise data, made for your own workflows, and ready to act autonomously with the speed that you need.

Through powerful ML pipelines, telemetry integration, and domain-specific AI agents, Ascentt is turning complex data into real-time decisions for the world’s leading automotive companies. Whether it is optimizing maintenance schedules or working on integrating digital twins into global manufacturing systems, Ascentt is getting things done – at scale.

Are you ready to build an end-to-end ML-powered maintenance pipeline? With over 18 years of delivering impact across automotive and industrial enterprises, Ascentt is your trusted partner for next-gen predictive maintenance. Let’s talk today!

FAQs

1. How does AI predictive maintenance work?

It uses AI to analyze data from sensors and telematics to predict equipment failures before they happen, preventing costly, unplanned downtime.

2. What is "Vertical AI" and why is it important for automakers?

Vertical AI is specifically designed for industries like automotive. It uses industry knowledge to provide more contextual and useful insights, leading to faster results.

3. How can my company get started with a predictive maintenance solution?

You can reach out to Ascentt for a consultation to discuss building a custom, end-to-end maintenance pipeline.