Production downtime is every manufacturer’s headache. When a line stops, costs rise and schedules slip. The surprising part is that the repair itself often takes only minutes. The real challenge is figuring out what went wrong.

Think about what usually happens on the floor:

- Engineers flip through thick manuals looking for the right page

- Technicians compare diagrams, logs, and sensor outputs from different systems

- Teams spend more time diagnosing than repairing

A simple fix ends up eating hours. A five-minute repair can mean four hours of downtime.

Does this sound familiar?

A global automotive leader faced the same problem. They partnered with Ascentt to change the way plant engineers and technicians handled troubleshooting. The result was a Generative AI-powered Repair Agent that reduced repair time from four hours to under ten minutes.

Use Case – Watch How AI Cuts Repairs from 4 Hours to 10 Minutes

The Challenge

Before the AI Repair Agent, engineers faced three major issues:

- Over 75% of repair time was spent on diagnosis, not on the actual fix

- Information was scattered across manuals, diagrams, and digital systems

- Switching between media wasted time and increased error risk

These issues led to long troubleshooting cycles and extended production line downtime. Engineers spent hours locating the right information while repairs that could take minutes were delayed.

The Solution

Ascentt built a Generative AI-powered Repair Agent tailored for production environments.

How it worked:

- Ingested real-time machine data and sensor signals

- Used Generative AI trained on manuals, repair logs, and diagrams

- Generated context-aware troubleshooting guidance for specific failures

- Delivered all insights through one unified interface

This approach eliminated manual searching. Engineers received step-by-step repair instructions aligned with the exact component and fault, allowing them to act immediately.

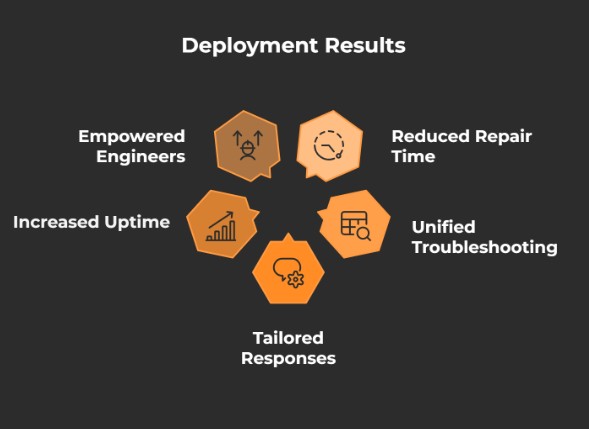

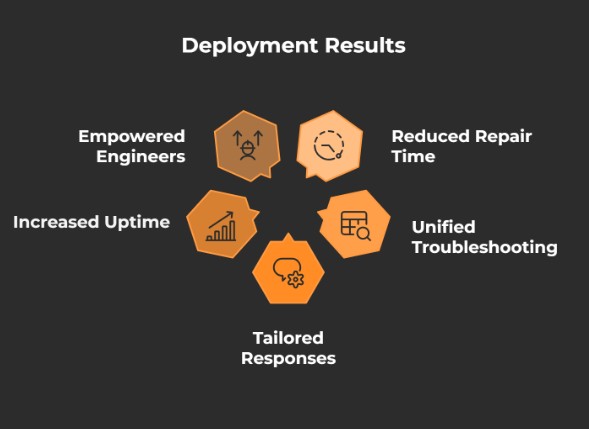

The Results

The deployment delivered immediate, measurable results:

- Repair time cut from four hours to 8–10 minutes

- Unified troubleshooting in one intelligent interface

- Responses tailored to the exact failure type

- Higher uptime and production efficiency

- Engineers empowered with real-time decision support

Why Industry-Specific AI Matters

Generic AI tools lack the precision for high-volume production. Automotive environments require solutions built with domain knowledge.

Key advantages of industry-specific AI:

- Domain intelligence built into the system

- Precision tuned for diagnosis and repair tasks

- Streamlined data flows from sensors and documentation

- Seamless integration into existing workflows

Automotive-specific challenges addressed:

- High-frequency connected vehicle and machine data

- Complex product configuration and repair lifecycles

- Shifting repair demands with electric vehicles and autonomy

Take Control of Downtime and Efficiency

The Generative AI-powered Repair Agent cut troubleshooting time from hours to minutes. Engineers were no longer trapped in manual searches or fragmented workflows. Instead, they had clear, context-aware guidance in real time.

We work with global leaders in automotive and manufacturing to reduce downtime, improve throughput, and optimize operations. Our AI and machine learning solutions are built to handle the complexity of enterprise systems and turn data into actionable outcomes in real time.

Our approach combines:

- Advanced data science and AI techniques

- Cloud-driven architectures built for scale

- Customized solutions designed for each client’s unique needs

- Expertise from a team of data scientists, machine learning engineers, and AI specialists with decades of combined experience

We are a trusted partner in shaping the future of industrial intelligence. Our focus is on delivering results that matter to enterprises—faster recovery, stronger efficiency, and higher production continuity.

If you are looking to build an ML-powered maintenance pipeline that transforms how your teams manage repairs, connect with us today. Surface enterprise-level results with Ascentt and move from downtime to real-time efficiency.

About Ascentt

Ascentt delivers enterprise AI, machine learning, and cloud-native engineering solutions. The company has more than 18 years of experience providing AI-driven systems for global enterprises.

Our approach turns complex enterprise data into real-time decisions that improve operations. We design scalable systems that integrate data-driven decision-making into core business processes.

For the automotive sector, we focus on:

- Reducing downtime

- Improving repair processes

- Increasing production efficiency

By transforming raw data into actionable steps, Ascentt helps manufacturers achieve faster recovery and stronger operational resilience.