For leading automotive OEMs, “Fix It Right the First Time” has become a core metric tied directly to service quality, customer satisfaction, and the bottom line. When repeat repairs rise, customer trust goes for a toss. Warranty claims swell, and technicians feel the pressure increasing.

One OEM resolved this issue using a data-driven approach. Learn how Ascentt’s AI Agent helped save millions in warranty costs.

The Problem: Too Many Variables, Not Enough Clarity

Dealer technicians aren’t short on data. Every service technician has access to critical service-related data. But just having data is not enough. Making sense of it quickly and effectively is an entirely different ball game. Here’s what hurts automotive technicians the most:

- Diagnostic codes are often complex and unclear: Technicians frequently face trouble codes that don’t directly point to the root cause, leading to confusion.

- Freeze frame data can be challenging to interpret: Without the proper context, snapshot data from the vehicle may mislead rather than inform the diagnostic process.

- Repair histories are often inconsistent or incomplete: Missing or vague service records make tracking what’s been done harder, risking repeated mistakes.

- Incorrect part replacements are common: Service technicians may replace the wrong components without a precise diagnosis, wasting time and resources.

- Repeat visits drive up costs and reduce efficiency: When the original problem isn’t fixed, customers return, increasing labor hours and damaging the service department’s performance.

The Solution: AI That Listens, Learns, and Guides

Every repair begins with a question: What’s really wrong here? Ascentt’s AI-powered Vehicle Diagnostics and recommendation Agent helps answer that faster and more accurately.

Ascentt’s AI-powered Vehicle Diagnostics and Recommendation Agent is trained on thousands of real-world repair outcomes. Using data science and machine learning, the system analyzes patterns across years of service records. It maps how specific combinations of DTCs, freeze frame data, and vehicle behavior correlate to actual root causes. It also learns to recognize the subtle cues that experienced technicians can miss under pressure.

Matching real-time vehicle data against a massive library of historical outcomes cuts through the noise and clarifies the technician’s work. Since it is built into the technician’s workflow, it doesn’t slow them down or force new habits.

When deployed in the field, the Vehicle Diagnostics and Recommendation Agent can do three things instantly:

- Identify the most likely root cause of failure

- Recommend the correct diagnostic path

- Suggest the ideal replacement part

The Impact: Measurable Results

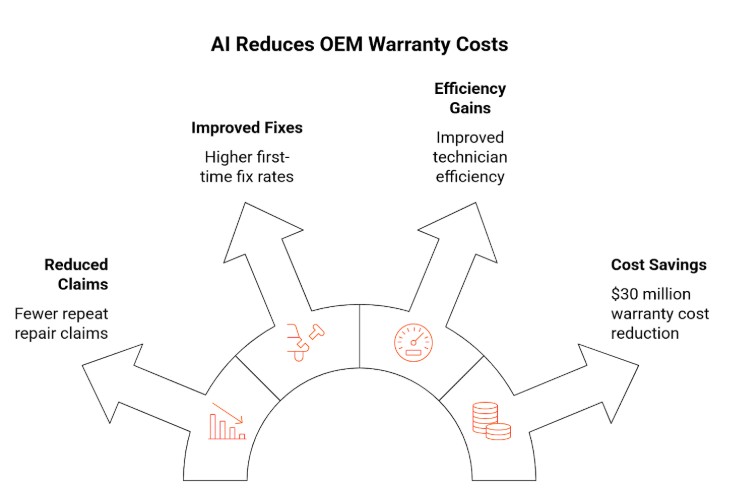

AI is becoming a critical tool for OEMs looking to control rising warranty costs. By analyzing diagnostic codes, repair histories, sensor data, and service outcomes at scale, AI helps identify the actual root causes of failures. This leads to more accurate repairs, fewer repeat visits, and measurable savings across labor, parts, and claims.

Once the AI Agent was deployed, technicians could save time on each visit. They could minimize misdiagnosis and ensure parts were installed right the first time. In the long run, this reduced repeat visits, directly impacting the brand’s reputation.

The OEM saw a measurable, repeatable shift in core metrics:

- Repeat repair claims dropped sharply: By guiding technicians to the correct root cause on the first visit, the AI reduced the likelihood of unresolved issues returning.

- First-Time-Fix Rates climbed: With real-time recommendations based on past successful repairs, technicians could follow accurate diagnostic paths and resolve issues on the spot.

- Technician efficiency improved: The system removed guesswork by surfacing the most probable fixes upfront, allowing techs to spend less time troubleshooting and more time repairing.

- Warranty costs dropped by over $30 million: Fewer incorrect part replacements and reduced repeat visits directly cut labor and parts expenses across the OEM’s dealer network.

Final Thoughts

Many AI projects stall because they aim too high or are too vague. Ascentt’s AI system succeeded because it focused on one real-world problem: improving diagnostic precision. The result? Fewer issues, better repairs, and millions saved.

Good service isn’t just about speed; it is also about accuracy. You don’t improve first-time fix rates when you give technicians the correct information at the right moment. You build trust. And the $30 million in warranty savings? That’s just the beginning.

For OEMs, it’s not just about cutting costs but also about improving service quality and protecting brand trust at the dealership level. If you want to implement a system that guides your technicians to the right root cause, streamlines the repair path, and builds customer trust, we can help! Speak to our AI experts to get started today!

Watch this video to learn more!