What you’re seeing in the featured image is a classic snapshot of industrial manufacturing — coordinated, repetitive, human-driven. But today’s assembly lines have evolved beyond what this photo captures.

Modern factories deal with hyper-connected assets, real-time decision-making, and production precision at microsecond speed. And when downtime happens, it doesn’t just interrupt workflows—it halts value creation.

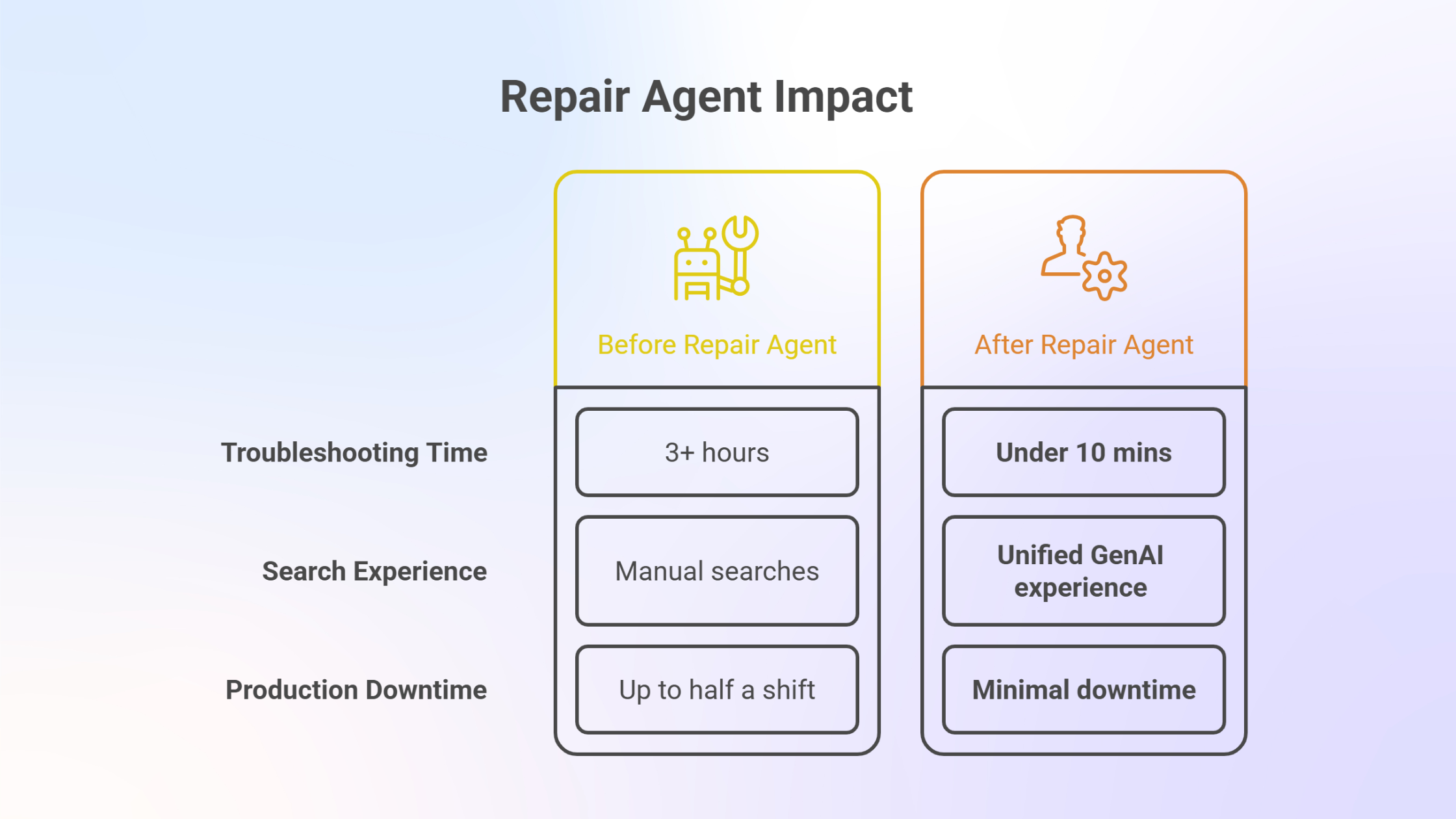

In this blog, we’ll show how Ascentt’s AI-powered Repair Agent helped a global automotive client reduce troubleshooting time by 90%, transforming breakdowns from four-hour headaches into ten-minute recoveries, all without disrupting the production rhythm.

In the automotive industry, time is not just money it’s throughput, customer trust, and competitive edge. And when production lines go down, even briefly, the ripple effect can disrupt an entire supply chain.

At Ascentt, we’ve seen one pattern repeatedly: It’s not the repair that takes time. It’s the troubleshooting.

That insight led us to build a domain-specific, generative AI solution, A Repair Agent that helped one of our global automotive clients reduce repair cycles from 4 hours to just 8–10 minutes.

Use Case – Process Vision AI in Action

Problem: Troubleshooting Is the Bottleneck

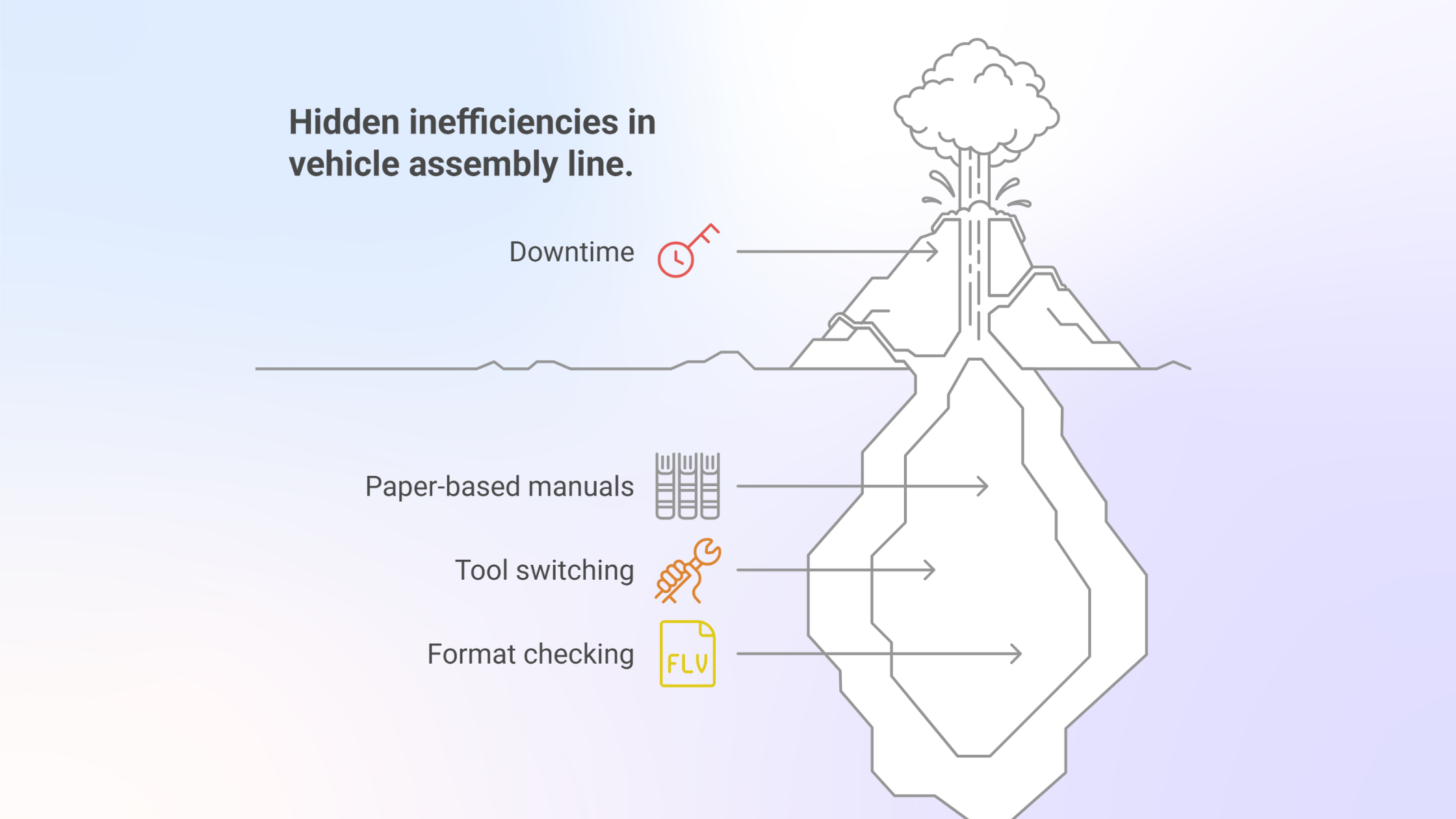

When assets on the vehicle assembly line failed, technicians lost valuable time hunting for answers:

- Searching through paper-based manuals

- Switching between tools and documents

- Checking multiple formats (PDFs, portals, videos) for troubleshooting steps

On average, 75% of the total downtime was spent identifying the problem. The actual repair only took 25% of the time.

This was a workflow issue, not a skills gap. And the fix wasn’t more documentation, it was smarter AI.

The Solution: Ascentt’s Custom Repair Agent

Ascentt deployed a vertical GenAI solution purpose-built for real-time asset repair.

What We Built:

· A centralized troubleshooting assistant powered by generative AI

· Integration with sensor data, CAN bus signals, and historical repair logs

· Dynamic guidance based on failure type, equipment class, and live inputs

Now, when an asset fails, technicians simply interact with the Repair Agent—no search, no guessing. The system generates step-by-step troubleshooting instructions specific to that component and failure pattern.

Key Capabilities:

· Multimodal intelligence — pulling data from sensor feeds, fault codes, and engineering logs

· Natural language interface — accessible via mobile/tablet on the floor

· Context-aware recommendations — generated in real time, not hardcoded

The Results: From 4 Hours to Under 10 Minutes

The outcome was immediate and measurable:

- 90% reduction in troubleshooting time

- Dramatic increase in first-time fix accuracy

- Maximized production uptime

- Faster resolution across shifts and locations

What used to derail a full production cycle was now resolved before it became a bottleneck.

Why Vertical AI Wins?

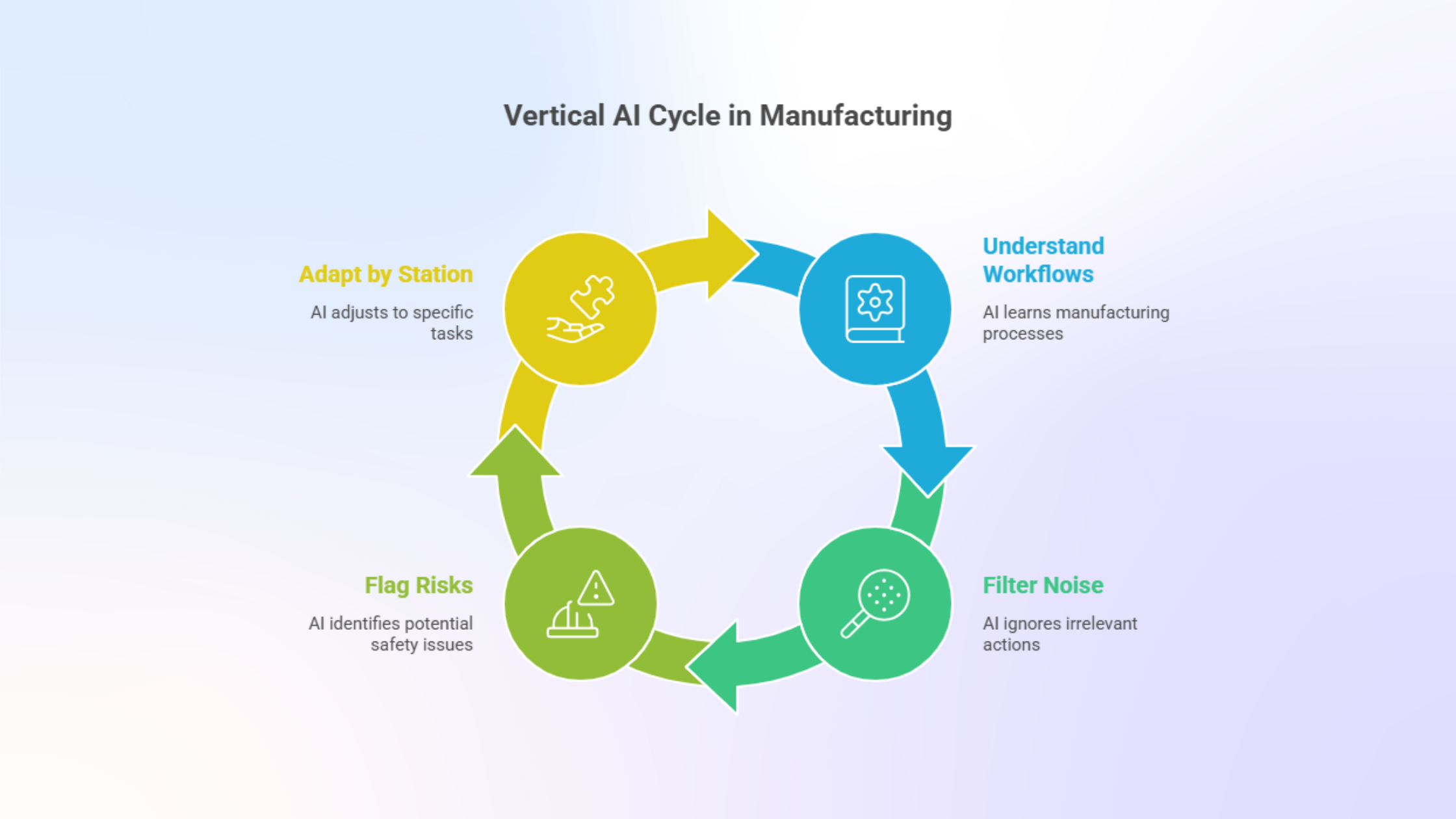

Vertical AI solutions are not just smarter. They are purpose-built for you, your plant and your environment.

At Ascentt, we don’t just build AI that works.

We build AI that understands why it needs to work—on your shop floor, in your environment, with your systems.

The Repair Agent is part of our larger Vertical AI strategy—where solutions are built ground-up for industries like automotive and manufacturing.

No generic templates. No retrofits.

Just solutions that scale because they’re rooted in reality.

Ready to Reduce Downtime Like This?

Ascentt’s Repair Agent is already transforming how leading manufacturers handle failureswith systems that:

-

Turn fault codes into action

-

Remove friction from diagnostics

-

Keep uptime high and stress low

Want to see it in action? 📩 Talk to our AI experts today.

Your next production delay could last 8 minutes instead of 4 hours.

The Bigger Picture: AI That Understands Your Plant

Unlike broad tools like ChatGPT or Gemini, Vertical AI combines machine learning with deep industry expertise to solve targeted challenges. Its market trajectory speaks volumes.

The global Vertical AI market will hit $115.4 billion by 2034, up from $12.9B in 2024, growing at a 24.5% CAGR. (Market.US)

Generic AI can’t handle the complexity of manufacturing. It sees data, but not the context.

Vertical AI is different. It’s built for the shop floor.

Here’s why it works:

- Understands your workflows: Pre-trained on manufacturing actions, not internet text.

- Filters noise, flags risks: Ignores casual gestures, but catches missed safety steps.

- Adapts by station: Knows the difference between engine assembly and welding—no reprogramming needed.